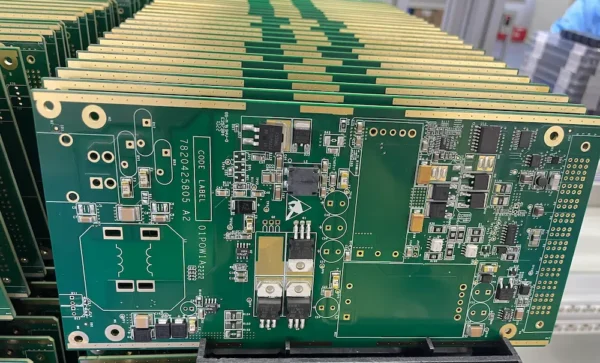

High-Precision SMT Assembly for Complex PCBs

From 01005 Passives to Large BGAs.

Trusted by European & North American OEMs for 15+ years.

Technical

Capabilities

Whether you need a quick prototype run or a stable low / large volume production batch.

- Lead-Free / RoHS Compliant

- IATF16949 Automotive Certification

- IPC-A-610 Class 2 & 3

| Parameter | Specification |

|---|---|

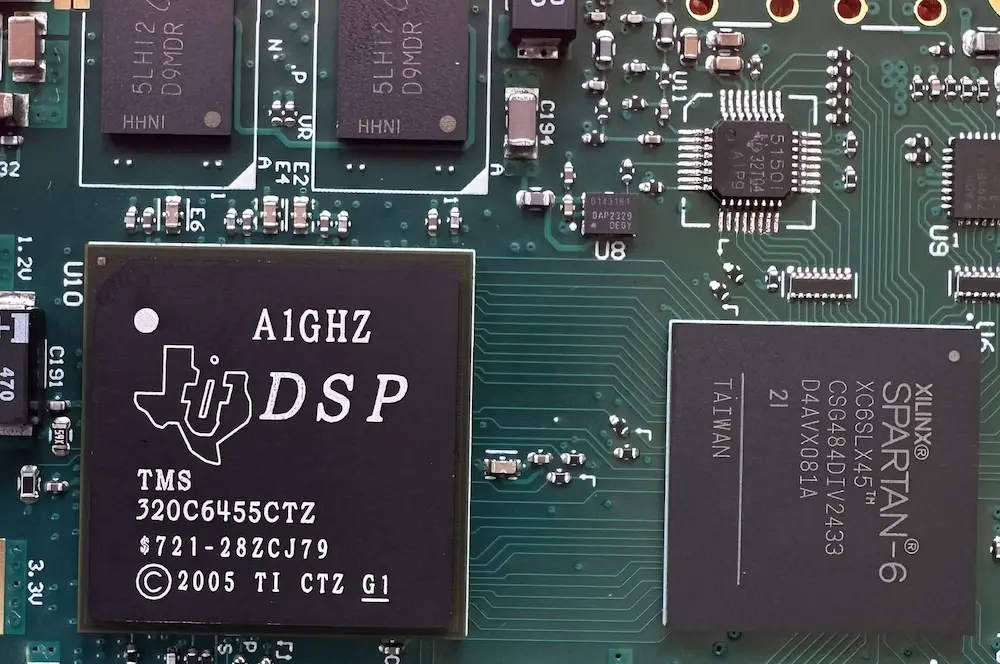

| Component Size | 01005 & 0201 Packages BGA, QFN, LGA, DFN Leadless Packages 0.3mm Fine Pitch Connectors |

| Placement Accuracy | ±0.035mm (Chips), ±0.025mm (QFP) |

| PCB Types | Rigid, Flex, Rigid-Flex, Aluminum (Metal Core) |

| Quality Control | 100% 3D SPI (Solder Paste Inspection) & Online AOI & X-Ray |

| Monthly Capacity | 52 million placements |

SMT Manufacturing Process

From nano-coated stencils to 10-zone nitrogen reflow, every step is data-driven.

Solder Paste Printing

Precision Solder Paste Printers with Nano-coated Stencils. Ensuring perfect release for 0.3mm pitch pads.

3D SPI

Detects volume & height deviations. Stops 95% of potential defects before components pick & place.

High-Speed Mounting

Handling complex BOMs from 01005 passives to large BGA/Connectors.

Reflow Soldering

Oxygen-free soldering environment (< 1000 PPM). Our N2 process enhances wetting, prevents oxidation, and delivers IPC Class 3 compliant solder joints.

We Don't Guess. We Verify.

Online AOI

Detects missing components & polarity immediately after reflow.

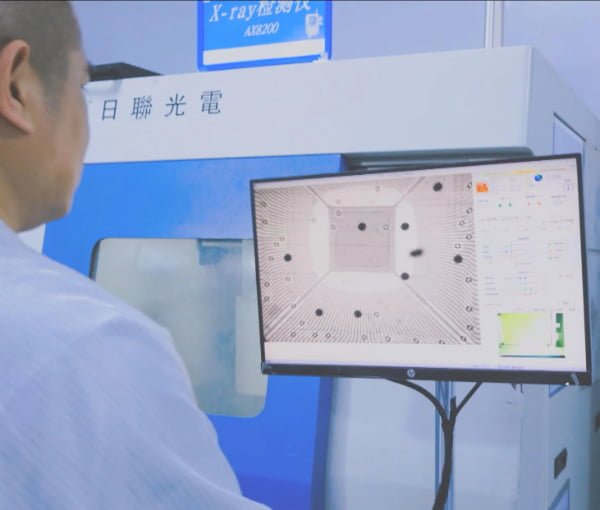

X-Ray Inspection

For BGA & QFN. We verify voiding < 25% (IPC Class 3) and check for bridges.

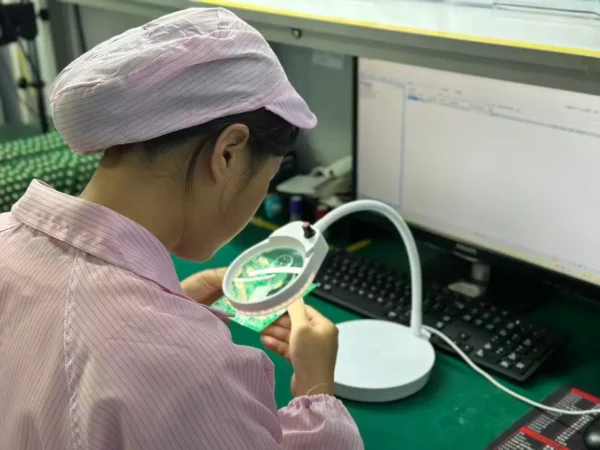

First Article Inspection (FAI)

Automated LCR measurement against BOM. Mass production starts only after 100% Pass.

IPQC Patrol

Regular line monitoring for ESD compliance, soldering temp, and operator standards.

Trusted by Industrial

Automation Leaders.

We specialize in mission-critical electronics where failure is not an option. Our process controls are rigorous enough for automotive and medical standards.

Defect Rate

On this 12-Layer project

Components

High density placement

Start Your Projects Manufacturing Today!

Whether you need a quick quote or technical consultation, we're here to help.

Quick Response via WhatsApp

Get instant answers to your questions

Connect directly with our technical team for immediate assistance.

We typically respond within 30 minutes during business hours.

Business Hours: Mon-Fri 9:00-18:00 (GMT+8)