")

")

Reliable

IC Programming

&

Functional Testing

for Complex PCBA

Stop worrying about defects in the field.

You Get Zero-Defect, market-ready electronics here.

Why IC Programming & Testing Is Where Most PCBA Issues Start

Most PCBAs don't fail in assembly -- they fail after deployment.

Wrong Firmware Flashed During Batch Programming

Without strict version control, entire batches can ship with outdated or incorrect firmware, causing mass recalls.

No Functional Testing = Hidden Defects

Visual inspection and AOI can't detect the components defects insides, firmware bugs, communication failures, or sensor calibration issues.

Inconsistent Programming Procedures

Manual programming processes lead to human error, missed steps, and unreliable results across production runs.

Lack of Test Documentation & Traceability

Without proper test logs, it's impossible to trace which units passed, failed, or were re-tested during production.

Late-Stage Failures Cost 10x More

Defects caught after shipping require expensive field service, warranty claims, and damage to brand reputation.

Supported Architectures

We support a wide range of microcontrollers, memory devices, and programmable logic

for all your IC programming needs.

| Device Type | Packages Supported | Interfaces |

|---|---|---|

| MCU / MPU | STM32, PIC, AVR, ARM Cortex, ESP32, NXP i.MX | SWD, JTAG, UART, ISP |

| Memory | NAND/NOR Flash, EEPROM, eMMC, SD Card | SPI, I2C, Parallel |

| FPGA / CPLD | Xilinx, Altera/Intel, Lattice | JTAG, SPI Flash |

| Wireless Modules | Bluetooth, WiFi, LoRa, Zigbee, NB-IoT | UART, SPI, Custom |

| Secure Elements | ATECC, TPM, Secure Boot ICs | I2C, SPI, Custom |

Fast Programming

Gang programmers for high-volume production

Secure Programming

Encrypted firmware & secure boot support

Full Traceability

Serial number logging & version control

See Precision in Motion

Watch how we handle your ICs with automated speed and rigorous testing protocols.

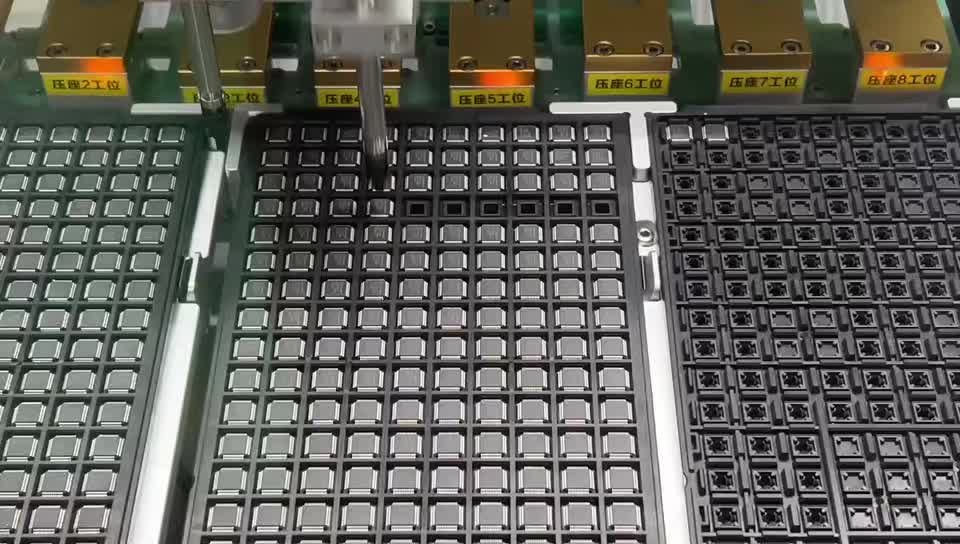

Automated IC Programming

3,000 UPH (Units Per Hour) throughput.

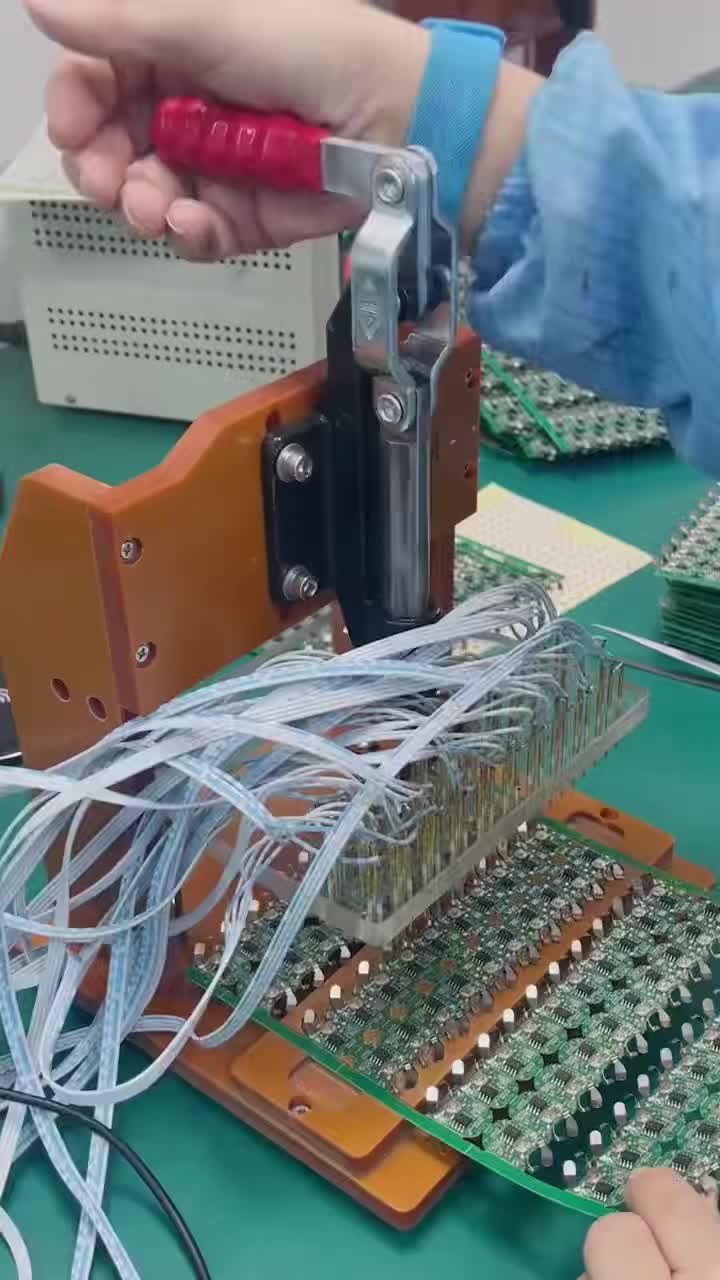

Customized Functional Test

Simulating real-world user inputs.

Power Supply Testing

Voltage regulation, current draw, and ripple measurement across all rails.

Communication Interface Testing

UART, I2C, SPI, CAN, Ethernet protocol verification and signal integrity checks.

Sensor Calibration & Validation

Temperature, pressure, motion sensors -- calibrated to your exact specifications.

LED & Display Testing

Automated visual inspection for LED brightness, color, and display functionality.

Wireless Module Testing

Bluetooth, WiFi, LoRa signal strength, pairing, and data transmission validation.

End-of-Line Pass/Fail Reporting

Instant feedback with detailed logs, serial number tracking, and failure analysis.

Stop Shipping DOAs

(Dead on Arrival)

Send us your test procedure. We will make the rest perfect.

Talk Via WhatsApp99.8%

First-Pass Yield

<0.1%

DOA Rate

100%

Traceability

The ACE Tech Testing Advantage

We don't just assemble boards -- we ensure they work perfectly before they reach your customers.

Custom Test Solutions

We design FCT fixtures tailored to your exact product requirements

ISO Certified QC

IATF16949, ISO9001, ISO13485 compliant testing procedures

Fast Turnaround

Prototype testing within 48 hours, production testing same-day

Full Traceability

Every unit logged with serial numbers, test results, and timestamps

Start Your Projects Manufacturing Today!

Whether you need a quick quote or technical consultation, we're here to help.

Quick Response via WhatsApp

Get instant answers to your questions

Connect directly with our technical team for immediate assistance.

We typically respond within 30 minutes during business hours.

Business Hours: Mon-Fri 9:00-18:00 (GMT+8)