")

")

Reliable

Conformal Coating Services

for Complex PCBA

Protect your electronics reliably

—while reducing long-term failure risks and maintenance costs.

Material Selection Guide

Choose the right protection for your specific application requirements.

Acrylic Conformal Coating (AR)

The most common choice for general electronics. Acrylic coatings are easy to apply, dry quickly, and offer excellent moisture and fungus resistance. They are also the easiest to rework.

- Cost-effective solution

- Easy to rework & repair

- High dielectric strength

Consumer Electronics, IoT Devices, Office Equipment

Silicone Conformal Coating (SR)

Designed for extreme environments. Silicone remains flexible over a wide temperature range (-55°C to 200°C), making it excellent for absorbing stress from thermal cycling and vibration.

- Extreme temperature resistance

- Vibration damping & flexibility

- Excellent humidity protection

LED Lighting, Automotive Electronics, Outdoor Sensors

Polyurethane Conformal Coating (UR)

The ultimate shield against chemicals. Polyurethane forms a hard, durable shell that provides superior resistance to solvents, fuels, and chemical fumes, though it is harder to rework.

- Superior chemical & solvent resistance

- Abrasion resistance

- Prevents tin whisker growth

Industrial Controls, Aerospace, Marine Applications

Customized Protection Strategies

From rapid prototyping to mass production, we align our coating methods to your volume and complexity—ensuring you never pay for tooling you don't need or wait for manual processes that scale too slowly.

Automated Selective Coating

Best for High-Volume & Consistency.

- Eliminates masking tape costs

- ±1mm precision for keep-out zones

Spraying & Dipping

Best for Complex 3D Geometries.

- Ensures full wrap-around coverage

- Ideal for hidden spots under ICs

Manual Brushing

Best for NPI & Quick Prototypes.

- Zero setup cost & instant start

- Perfect for urgent sample runs

Prevent Field Failures

Before They Happen

A coating is only as good as its verification. We don't just apply protection; we prove it. By strictly following IPC-CC-830 standards, we ensure your boards survive humidity, salt mist, and thermal shock.

Contact Engineers Via WhatsApp100% UV Inspection

Eliminates "skipped zones." We ensure moisture finds no entry point.

Salt & Mist Check

Guarantees corrosion resistance even during long ocean shipping.

Thickness Check

Verifies dielectric strength. Too thin = short risk; Too thick = cracks.

Adhesion Testing

Ensures coating won't peel off under thermal shock or stress.

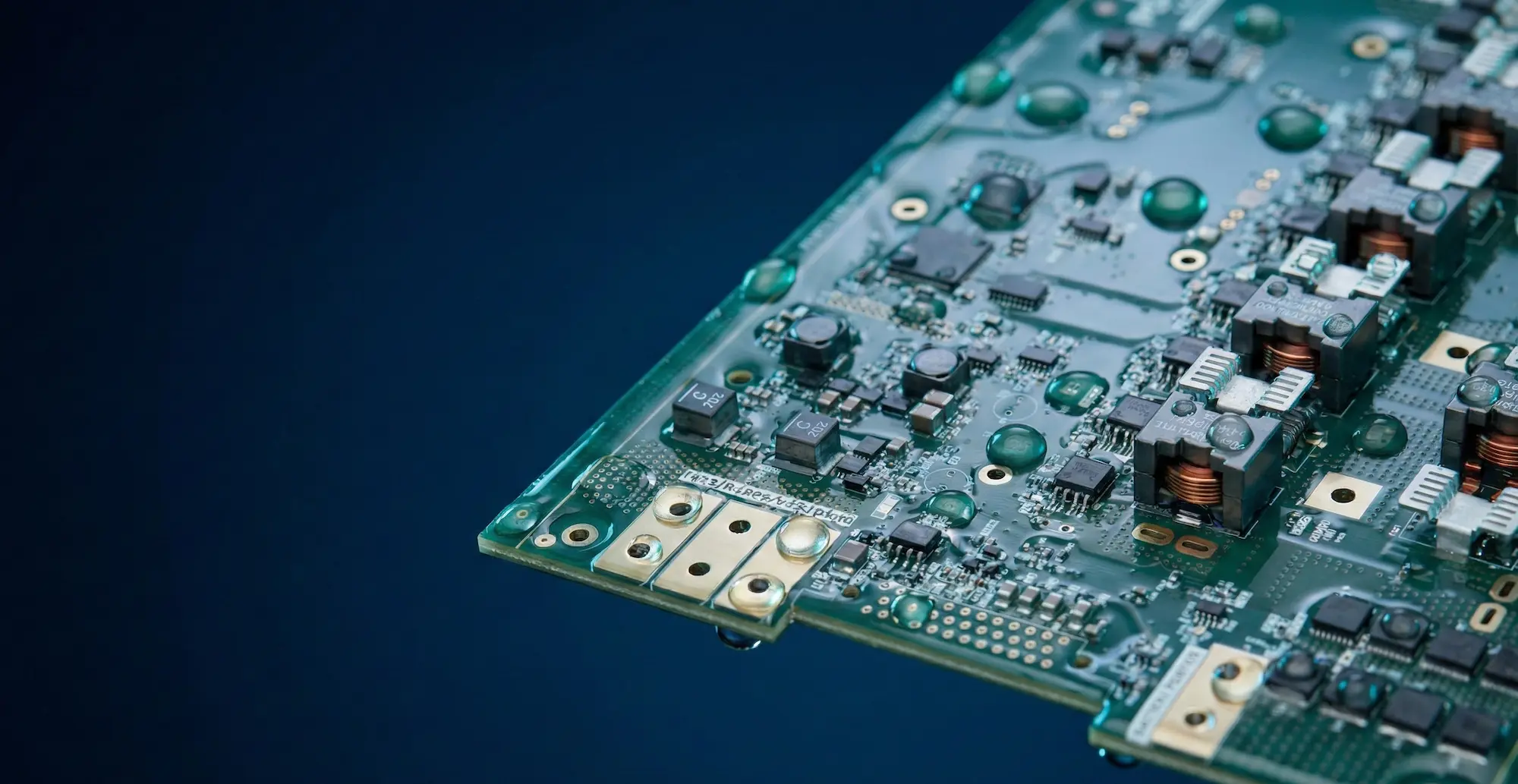

State-of-the-Art Facility

A glimpse into our conformal coating production line.

IPC-CC-830

Qualified to IPC standards for reliability and performance.

UL 746E

Using UL-certified coating materials for safety compliance.

RoHS & REACH

Fully compliant eco-friendly materials available.

Full Traceability

Batch tracking for all coating materials and processes.

Success Stories

Automotive Communication Module

Challenge: The Communication Module faced extreme thermal cycling and road vibration. Standard coatings were cracking.

Solution: We applied a high-flexibility Silicone (SR) coating with automated selective spray to avoid connector pins.

Material

Silicone (SR)

Result

0% Field Failures

Agricultural Soil Monitor

Challenge: The Agricultural Soil Monitor runs 24/7 outdoors in farmland soil, enduring extreme environmental erosion from UV radiation, rainfall, acidic substances and dust.

Solution: Dip-coated the PCB with conformal coating. Encapsulate the PCB with a custom-molded white polyurethane casing of 65D hardness, which is formulated with UV inhibitors for enhanced outdoor durability.

Material

Polyurethane (UR)

Result

Extended Lifespan 3x

Frequently Asked Questions

What is the typical coating thickness?

Typically between 25-75 microns (1-3 mils) for acrylics and urethanes, and slightly thicker for silicones (50-200 microns), depending on IPC standards.

Do I need to worry about connectors?

We will physically mask the connectors if using the manual brushing or spraying or dipping ways. If with our automated selective coating, we program the machine to avoid keep-out zones like connectors and switches with ±1mm precision.

Can you coat under BGA components?

Standard spraying relies on capillary action to reach under components. For full underfill protection, we recommend a dedicated underfill process before coating.

How do you test the coating coverage?

All our coating materials contain UV tracers. We perform 100% visual inspection under UV black light to ensure complete coverage and identify any de-wetting.

Start Protection for Your Projects Today!

Whether you need a quick quote or technical consultation, we're here to help.

Quick Response via WhatsApp

Get instant answers to your questions

Connect directly with our technical team for immediate assistance.

We typically respond within 30 minutes during business hours.

Business Hours: Mon-Fri 9:00-18:00 (GMT+8)